|

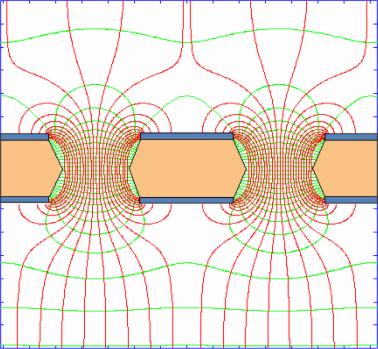

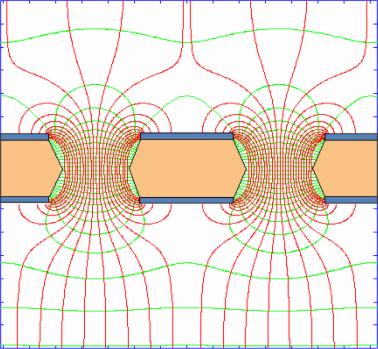

| Electric field in GEM holes |

|

ATTENTION The use of GEM foils as Radiation Detectors is covered by two patents: Compteurs ŕ Trous (CAT) (US 5 742 061) owned by CNRS and Gas Electron Multiplier (GEM) (WO9921211) owned by CERN. Such use requires a license. CERN grants royalty-free licenses for Research and Development use of GEM foils. Commercial licenses can be granted on conditions to be agreed with CERN.More information about GEM licencing can be found at http://cern.ch/gem. CERN would appreciate that users of GEMs put the above text on their web site. |

The development of the GEM manufacturing process is an excellent example of the use of a core knowledge that CERN owns. Together with Fabio Sauli (the inventor of the GEM) and the Technology Transfer division we will pursue the development and transfer the manufacturing technology to industry.

The gas electron multiplier (GEM) consists of a thin, metal-clad polymer foil, chemically pierced by a high density of holes. On application of a difference of potential between the two electrodes, electrons released by radiation in the gas on one side of the structure drift into the holes, multiply and transfer to a collection region.

The multiplier can be used as detector on its own, or as a preamplifier in a multiple structure; in this case, it permits to reach large overall gains in harsh radiation environment.

|

| Electric field in GEM holes |

In the late 1990's the GEM manufacturing technology has been developed at CERN in the printed circuits workshop by A. Gandi and R. De Oliveira. A metal-clad polymer foil (copper on kapton) is coated on both sides with a photosensitive layer and exposed to UV light through a mask reproducing the desired holes' pattern. The metal is chemically removed in the holes, and the foil is immersed in a solvent for Kapton.

|

| The first large size GEMs produced in the PMT workshop for HERA-B. (left to right: Angelo Gandi, Rui De Oliveira and Jean-Claude Labbé) |

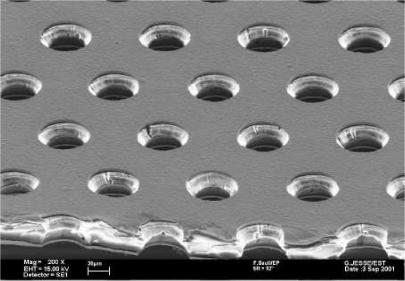

The resulting foil has conductor on both sides, pierced by a high density of holes (typically 70 µm in diameter at 140 µm pitch). Close to a thousand GEMs of various shapes and sizes have been built so far, both for the requirements of HEP experiments (HERA-B, CMS, COMPASS, LHC-B) and for other applications.

|

| Close view of a GEM electrode |

| 14 March 2003 | As GEM detectors are becoming such a success, the requests for production are difficult to follow for us as the DEM labs are set up for prototype quantities. That is why we are actively looking for an industrial partner who can fabricate the foils and who can possibly do the framing as well. |

| 19-25 October 2003 | Nuclear Science Symposium Portland. Over 30 (!) oral presentations presented results of tests and simulations of GEM detectors. |

| 29 October 2003 | Decision to transfer GEM technology to a member-state company that has already a licence for microvia technology. First prototypes expected before the end of the year. |

| 21 September 2006 | CERN keeps up production of GEMs and has reduced delivery times. Standard sized GEMs (50x50 and 100x100 mm) are even in stock. |

| 1 June 2007 | German startup company "CDT CASCADE Detector Technologies GmbH" founded by former staff of University of Heidelberg. This company makes fast neutron detectors based on GEM technology. |

| 18 March 2008 | On-going innovative research to produce large GEMs (60 cm x 40 cm and

larger). Progress with development of easy to manufacture spark-protected resitive GEM technology. |

GEM Patents

A GEM of a detector! (CERN bulletin article, french version)

A marriage of pixels and proportional counters, (CERN Courier July/Agust 2004)

Commissioning of the GEM Detectors in the COMPASS Experiment, Frank Simon, Physik Technische Universitaet Munich, November 2001

Development

of a gaseous detector based on Gas Electron Multiplier (GEM) Technology

F.Murtas

(LNF-INFN), Nov.2002

Development of a GEM-based TPC Readout for Future Collider Experiments, Steffen G. Kappler, Institut fuer Experimentelle Kernphysik, Universit¨at Karlsruhe, Dissertation 2004.

Developments and the Preliminary Tests of Resistive GEMs Manufactured by a Screen Printing Technology, G. Agócs, B. Clark, P. Martinego, R Oliveira, V. Peskov, P. Pietropaolo, P. Picchi, Journal of Instrumentation Volume 3, February 2008.

CASCADE a High-Rate Detector for Neutron Applications in Science and Research, University of Heidelberg

technical questions on GEM physics