NEWS 2003

Need a few cables quickly?

26 November 2003. As one of our services we can make electrical

cables. We have in stock most standard connectors and cables, so especially for

test beams where often just one or two cables are missing, we often can help you

out quickly. An example of a happy user is the n_TOF experiment as the following

extract of an e-mail shows:

From: Helmut Wendler

Sent: Tue 25-Nov-03 18:35I like to express my gratitude about a

recent "rush" cabling job done by your wiring and cabling workshop in

building 3. There were several aspects about it, which I like to mention: 1) I

needed urgently 2 cables for the n_TOF experiment that needed 9 pin Cannon

connectors fitted. 2) The necessary cables and connectors could be found

in the workshop, thanks to the small stock available there. 3) It was

therefore possible to have these cables within 24 hours.

....

I like to take this occasion to thank all your people, who are very

dedicated to their work and their willingness to help to get things done

quickly. This service is very important for "small" experiments and

set-ups for test beams where time is at a premium.

Last but not least experiments, despite all provisions and planning,

always have a need of such a service since they need things done very

quickly such that they do not delay the start-up of an experiment or

losing beam time due to lack of few items, which your service provides

promptly.

|

NA60 Indium run finished

24 November 2003. As can be seen from the DEM

news article from 6 October, DEM was deeply involved in the design of the

NA60 Pixel detector. The collaboration kept the DEM group up to date of the

progess:

From: Ernst Radermacher

Sent: Thursday, 20 November, 2003 11:54 AMThe NA60 indium run

is over. It was very efficient and successful thanks to the good

performance of all the detectors. Especially to be mentioned is the

Pixel detector which has safely overcome its crucial test and was

essential for the quality of the physics data. Many people, inside and

outside of NA60, contributed largely to this success. Let's

celebrate this occasion with a party... |

Another service: expertise of subcontractors' quality

|

13 November 2003. For the LHC accelerator, the

AB division needs 11000 printed circuits of one type. These circuits will

be produced by a company that CERN did not work before with. To asses the

production quality, the DEM service expertised several test boards before

AB decided to send the order for the full production. The expertise

measured the amount of warping (bending) of the boards, the thickness of

the various layers (solder mask, copper, FR4) and also assessed the quality

of the metallization of the vias. For this a side cut of the board was

made of which you see to the right an example. The two holes are vias in

the card, while the light areas are metal layers.

Apart from the detailed measurements, the conclusions

of the expertise were that there is a good overall quality, but that the

nickel/gold passivation layer was a bit too thin (it should be 4 to 5 um

while it was only 2), and that the screen printing was not well defined in

some places.

So if you have some doubts about the quality of a

certain board or a subcontractor, don't hesitate to ask us for advice.

Often we can even help the company to improve the quality if there are any

problems. |

Side view of a cut-through of a 6-layer PCB showing

two vias and internal layers |

SMD assembly vacancies filled

13 October 2003. The board for the two Local Staff positions in the

SMD assembly service run by Claude Millerin has been held. We have selected two

excellent candidates who, if everything goes well, will take up their positions

still this year.

There is still a

vacancy open in the PMT section for someone to produce high-density

circuits in the cleanroom.

9 October 2003. We've made an easier to use alias to our web site:

http://cern.ch/dem. This is easier to remember

than the http://cern.ch/est-div-dem

that most likely will change because of the coming merger of the EST and ST

divisions into a single department. The alias also works for complete pages:

e.g. http://cern.ch/dem/news will bring

you immediately to the newspage from your electronics helpers.

DEM frees the quarks

|

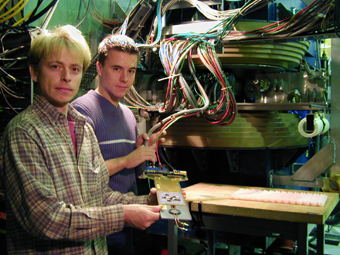

6 October 2003. The photograph on the front-page of the

CERN Bulletin article "NA60 frees the quarks", shows the read-out

board that has the silicon pixel detector chips mounted on it. The pixel

chips are mounted on a thick-film ceramic hybrid that in turn is mounted

on standard FR4 material. NA60 was so proud and happy of those

boards that were designed, built and assembled by DEM, that they selected

it as the favorite photo for the front-page. If the Bulletin would have

had a centre-fold, a more detailed

photo could have shown the full beauty of it.

For more background on NA60, please read the

weekly bulletin article. |

Standard delivery in 10 weeks, near-miracles in 10 days

29 September 2003. As we repeat quite often in contacts with our

clients, the turn-around time (from your schematic to a fully designed,

fabricated and mounted board in your hands), is normally around 10 weeks . Of

course this is part of a negotiation that depends on the complexity of your

design, how many designs we have going on for your collegues and of the deadline

that is absolutely required for your project.

In some cases it makes that we put everything on everything to get your

project out as soon as possible. Unfortunately this can make that projects of

your collegues at CERN will be delayed in favor of your's. In that view it is

best to stick to realistic plannings to keep everyone happy.

That said, in July we had a very urgent request from the

experient TOTEM. For reasons outside of the control of the responsible engineer,

two boards had to be designed with a very high urgency. If we would miss the

deadline, no measurements could be made on the testbeam, while the next run for

them would be only in May 2004! In this case we made the full design, fabrication of a kapton

board and the assembly of the components in 10 days only. The second board that

uses fine-pitch PCB design took just a little longer. You see, if necessary,

it can be done. But only if everyone plays the game correctly. We appreciate the

following thanking letter (and the invitation to the celebration drink :-)

| Nous voudrions vous remercier pour

le travail fait pour TOTEM. Il y a eu le kapton et le circuit imprime qui

ont ete fini en temps record, meme si specialement pour le kapton il y

avait pas mal de choses non-standard. Le turn-around pour le circuit

imprime a ete 10 jours du demarrage du design a la finition de la

fabrication. Pour le kapton ca a ete tres rapide aussi.

Personnellement je voudrais vous remercier pour votre bonne volonte et

souplesse dans votre aide pour ce projet. Ca n'a pas ete facile, et

c'est presque un miracle qu'on a pu monter tout ca dans un delai si reduit.

Grace a vous l'experience TOTEM a pu obtenir des donnees sur ses nouveaux

detecteurs au faisceau, donnees essentielles pour la conception finale de

l'experience. |

Being there: helping out of troubles

10 September 2003. One important aspect of the DEM group is the

expertise that we have readily available. Below you can find a few examples of

the usefulness of this for the experiments.

After an extensive market survey and request for offers, an Italian company

had the best price for the production of several thousands of ELMB modules

(small processor boards with I/O). However, nobody had any experience with this

company, so before the contract could be awarded, a visit to the company was

needed. Therefore ATLAS requested Marcello d'Auria, who has an extensive

experience with PCB production and assembly companies, to do this visit. After

the visit on 4 September, Marcello concluded that the company was very good and

could produce the modules, but with the remark that only the newest production

site of this company should be used.

On 9 September Rui de Oliveira visited a subcontractor for one of the large

LHC experiments to solve problems were circuit boards delaminated. The

experiment was happy: "I would like to thank you again for your support at

our meeting with the subcontractor today. Your expertise has helped a lot in

understanding the problems and was essential in defining the plan for the next

steps."

On 10 September one of the experiments had troubles with a wire chamber

module made on ceramic circuits. The circuit had too much leakage current, even

after extensive cleaning done by the physicists. They came to Rui to ask for

help, who knew better which type of dissolvants to use in this. Rui cleaned the

circuit and now the problems have disappeared.

Peeping through a hole

BGA Inspection system

aquired in September 2003 |

5 September 2003. Already since a few years we mount BGA

components in the assembly workshop. However, for a final inspection we

had to send boards outside for an X-ray check. Normally this isn't

necessary as BGA's have a much smaller risk of bad solder joints compared

to IC's with pins. However, in case there are problems, it is good if we

can do a quick check on the CERN site. Reason for which we recently

acquired a visual inspection system that can look from the side under the

BGA. The system works with a high-resolution camera with a tip that has a

mirror at the end. If you thought that looking through a keyhole isn't

easy: we can now look through a space as low as 0.05 mm!

To have an idea what we can do with this system (after some training

:-), you may have a look at

the web page or

the video from

the vendor. |

Job offer: High-density circuit fabrication in

cleanroom.

Your creations will be as close to the Big Bang as possible!

28 August 2003. In the

Photolithography and Microconnectics Technology section where we build

high-density circuits on glass, ceramics and other substrates, we need an

electronics technician who can work very precisely. Most of the work you will do

in a Class 100 cleanroom.

After an initial training you will be able to build circuits with line widths

downto 5 mm! Your work (which is a CERN core

technology) will be absolutely invaluable for the next LHC experiments and

beyond. These circuits are for example used very close to the point where the

particle collisions happen. In a way the circuits that you build will be the

ones closest to the place where our particle accelerators create the same

circumstances as existed just after the Big Bang!

If you are interested in being part of the search for the smallest particles

ever, please read the

Vacancy Notice

and apply! Be fast, you can apply until 6 November 2003.

Job offer: SMD assembly - the data will pass

through your solder-joints!

25 August 2003. In the SMD assembly workshop

we solder Surface Mounted components on printed circuit boards that are used in

the particle accelerators and inside the particle detectors. We specialise in

the assembly of prototype boards and in the quick repair of boards (including

Ball Grid Array components and SMD components downto 0201 size).

In this workshop we need two techniciens. If you have experience in mounting SMD components

or are willing to learn to work with these, please read the

Vacancy Notice and apply!

Preparations of circuits for bonding silicon detectors and ICs

12 June 2003. On 11 and 12 June at CERN a workshop on Bonding and Die

Attach Technologies was held. The scope of this workshop spanned wire and TAB

bonding, bump bonding, glueing techniques and methods to assess the bond

quality.

Rui de Oliveira of the EST-DEM-PMT section made at this workshop a

presentation titled:

Abstract

There are only a few materials that are reliable for bonding,

but many ways to create a structure to be bonded. In this presentation an

overview on the metallurgies that are commonly used for bonding with their

benefits and inconvenient will be discussed.

More information and the transparencies of all presentations can be found at:

http://www.cern.ch/ssd/bond

Symbol creation form

11 June 2003. One of the services of the Electronics design office is

to create symbols to use in your schematics and PCB symbols (padstacks) for the

CERN supported CAE programs Cadence and PCAD. To help you in providing us

complete information when you request a symbol, we provide you a

form (in

Word) to fill in which you can send to our mailing addresses

electronics-components-pcad@cern.ch or

electronics-components-cadence@cern.ch.

11 June 2003. One of the services of the Electronics design office is

to create symbols to use in your schematics and PCB symbols (padstacks) for the

CERN supported CAE programs Cadence and PCAD. To help you in providing us

complete information when you request a symbol, we provide you a

form (in

Word) to fill in which you can send to our mailing addresses

electronics-components-pcad@cern.ch or

electronics-components-cadence@cern.ch.

Presentation EST-DEM

30 May 2003. On 14 May the EST Technical seminar had as subject the

EST-DEM group. The presentations made are now available. The presentation of

Erik van der Bij explains the

general services that EST-DEM provides, while the presentation of Rui de

Oliveira described the

fabrication of several special circuits used in the experiments CAST

(micromega) and NA60 (silicon pixel vertex spectrometer).

Première note en français

28 Mai 2003. La division AB (Accelerators

and Beams) a fait une note

d'information (en français) concernant l'utilisation du bureau d'études EST

DEM-BE.

First ELMB Production

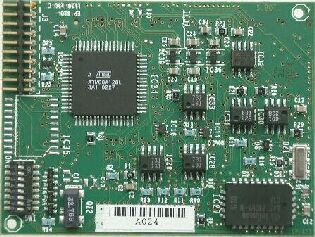

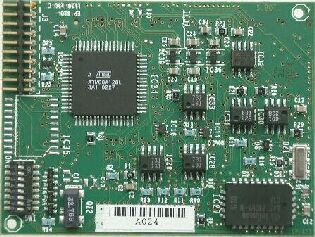

|

ELMB128 in the analog version |

21 May 2003. The

Embedded Local Monitor

Board ELMB128 is a processor board with analog and digital I/O. Among

others, it is used in the ATLAS Detector Control System, but also other

experiments are interested in using it.

Marcello d'Auria of the DEM group has organised of the first production of

the module, i.e. he found the company who could produce and test the first

batch of 800 boards and negotiated the price of the production, including

the testing.

The design office of DEM has also produced

all the production files and stored them in EDMS (analog

and digital

version).

As can be read in the

ELMB128 Test

Production report, the client is happy: "The ELMB128 2002 production was

organised in an excellent way by the CERN EST-DEM group. The ELMB128 cards

were delivered fully tested and on schedule. The price per unit has been

reduced to 55% of the previous production." |

Cables: from prototype to large-scale production all with EST

21 May 2003. In the EST-LEA group is a team that can make cables in

large quantities. The team, lead by Christian Dechelette (formerly led by Mr.

Steinberg), also fabricates small mechanics such as crates and can wire up

crates, similar as is done in the DEM-WS section. We have decided to unite our

forces so now you have a single entry point for making your cables:

Christian Dechelette.

EP division participates in aquisition of electrical tester for PCBs

20 May 2003. Until now all printed circuit boards and other special

circuits that were produced in DEM that needed an electrical test to be done,

where sent out to an external company. Although this company could do the test

within a day, with the necessary transport this created of course delays which

were in the order of a week. Also for the PMT section where the boards are

built, it was very difficult to work with such a delay on the feedback on

quality. Therefore we have decided to buy an electrical tester. As the tester is

expensive (well above 100 KCHF) the EST division has requested the EP division

(who is our main client) to participate. EP management generously has decided to

pay half of the cost of the tester for which we are of course thankful.

DEM in Technology Transfer database

9 May 2003. The Education and Technology Transfer

division (ETT) of CERN has ask task to promote technology transfer. The

DEM group is in this database with the following Short Description.

|

A dedicated printed circuit board service provides support

for CERN users, and can deal with special requirements in terms of pitch,

geometry and special materials for printed circuit boards. The service can

provide layout, fabrication and component placement services. Having these

facilities in-house has allowed the service to gain a deep understanding

of design and manufacturing aspects, and be well-positioned to provide

consulting and support for applications with special requirements. |

In the

technology transfer database you can find the full description of the

DEM entry as well as other entries such as our involvement with

our patents on GEM detectors and

special circuits with good thermal management characteristics.

EST Technical seminar by DEM

8 May 2003. On 14 May we will give a presentation about the DEM Group.

We will tell you which services we proved and we will also show you examples of

special circuits that have been fabricated in the Photolithography &

Microconnectics Technologies section. See the

CERN agenda

for more information (location)

New generic e-mail addresses for DEM

16 April 2003. The EST-DEM service has now generic e-mail

addresses where you can send your requests for schematic and PCB symbols for the

CERN Cadence and PCAD libraries to. Please use those addresses instead of the

direct e-mails of the people responsible. This to make sure that during holidays

we can still handle your requests correctly. Note that we also have generic

adresses for the design office and the electronics assembly workshop.

Update 17 July 2003. On request of the CERN (book) library, we had to

change the e-mail addresses of the component creation requests from ..-library-

to ..-components-. We're sorry for the confusion that it may have led to you.

The table below shows the correct mailing list names.

DEM supports LHCb promotion to use halogen free PCBs

14 March 2003. The technical coordinator of the LHCb experiment

wrote the following to its collaborators:

| The question of use of halogen free PCB materials have

been asked a few times lately by LHCb collaborators. I will do my best to

summarize the situation quickly.

The halogens (mainly Br) is considered problematic to the

environment when electronics is scrapped. The EU is therefore planning to

forbid its use in the long term future (at some time before 2010).

Materials with halogens also develop problematic smoke in case it burns

(its addition is in fact made to prevent the material catching fire!) and

therefore also becomes a safety issue (TIS).

CERN TIS would very much like to forbid the use of halogenated PCB

materials but this is at the current state of things considered to be too

problematic and may in some cases imply unacceptable price increases (but

the price difference is getting smaller and smaller). For commercial

modules it is in most cases impossible to enforce a halogen free policy.

All cables must though be halogen free ( No PCB plastic in cables).

The current situation is therefore that it is highly encouraged to

use non halogen materials for PCB's if possible. Please make all price

inquireries on PCB manufacture include a quote for the option of halogen

free materials. If the price difference is small then it will be hard to

justify the use of the traditional FR4 material. Technical advice on the

practical aspects of halogen free PCB materials can be obtained from the

CERN PCB design and manufacturing service EST-DEM. |

Indeed, DEM is available for questions on halogen-free PCBs. Moreover, we can

even produce your prototype boards with halogen-free materials that we do have

in stock. In fact we will apply no price increase for the halogen-free PCBs.

For further details please contact

Rui de Oliveira.

Want to become Manager of the CERN Electronics Design

Office?

13 March 2003. You're a technical engineer in electronics and

like to see that most electronics designs made at the world's largest research

centre in Particle Physics will pass through your hands? Then we have got the

perfect job for you!

We have just opened a post for Manager of the Electronics Design

Office, which is part of a successful service group. In the

Vacancy Notice you can find all details about this position in the

international working environment of CERN.

Be fast to apply, 20 May is about the latest moment you can send

in the application letter for the job you always have dreamt of.

Have a look at the EST-DEM web pages to see what it's all

about. Contact Seamus Hegarty

(Human Resources), Erik

van der Bij (group leader) or

Marcello d'Auria (current

manager of the design office) if you have any questions about this post.

Good designs never die

7 January 2003. DEM got a request for the production of 25 cards that

were designed some 9 years ago. Without any problem we could find back the

films (which are still usuable) for this double-sided circuit and also the files

used for the drilling were still available on floppy. Several times a year we

receive requests for the fabrication of really old circuits. For example,

November last year we had to reproduce cards that were designed some 15 years

ago!

We store all new designs in electronic form in EDMS, to be even more sure

that we can find back in 15 years time the designs that you make right now.

EDMS has also the advantage that you can access directly all files over the web.

6 January 2003. Holidays are over and we can accept again new requests

from you for the design, production and assembly of your printed circuit boards

and microdetectors. Please count on 10 weeks between the

moment you give us your schematics and the moment that you will receive assembled

prototype in your hands.

Old news

11 June 2003. One of the services of the Electronics design office is

to create symbols to use in your schematics and PCB symbols (padstacks) for the

CERN supported CAE programs Cadence and PCAD. To help you in providing us

complete information when you request a symbol, we provide you a

11 June 2003. One of the services of the Electronics design office is

to create symbols to use in your schematics and PCB symbols (padstacks) for the

CERN supported CAE programs Cadence and PCAD. To help you in providing us

complete information when you request a symbol, we provide you a